Dry Fog Humidity Control for Bread Coolers

Use Dry Fog for increased control over humidity

Humidification Systems for Bread Coolers

During the baking process, whether the product is bread, confectionery or other baked products, cooling is an integral stage of the food processing industry.

Coolers are essentially large ventilated boxes where temperature and humidity are tightly controlled by air flow variance and which traditionally use standard hydraulic water sprays. In typical circumstances, the temperature in the cooler is maintained to approximately 20 degrees C while the humidity is held at around 85-90%. If the bread is not cooled sufficiently it can collapse when slicing and cause condensation on the inside of the packaging.

Dry Fog Humidification

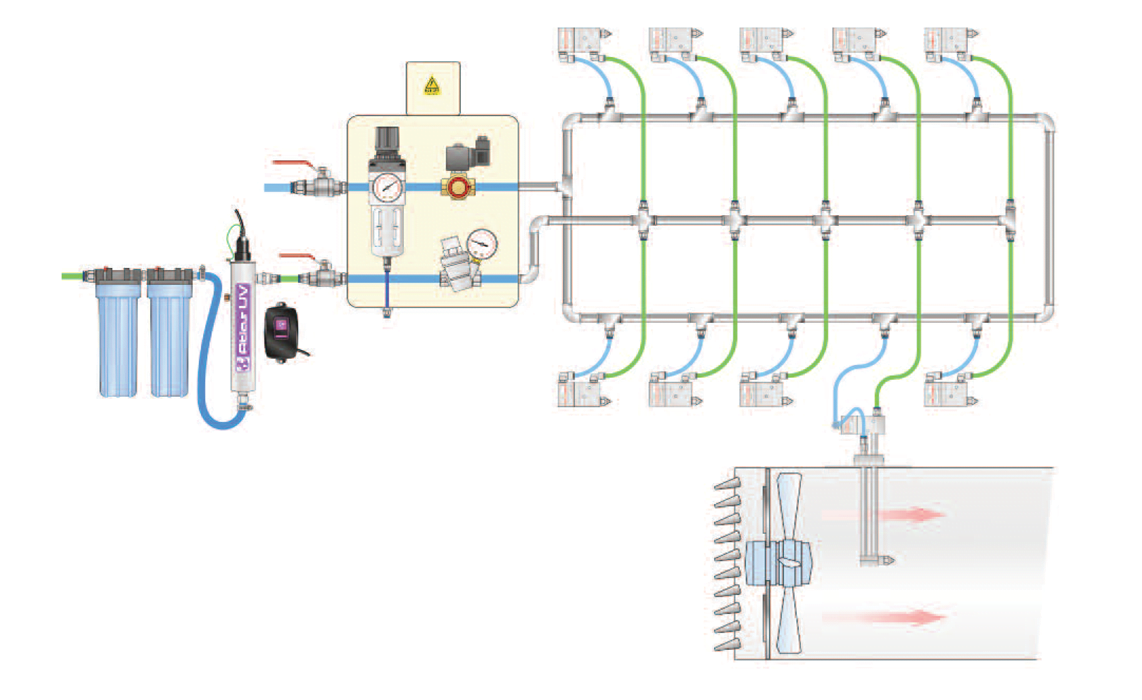

By replacing the existing traditional water sprays with our Dry Fog system it allows for greater control over the relative humidity within the cooler, increased efficiency and reduced water usage.

The Dry Fog nozzle assembly uses compressed air and water to create an ultra-fine spray consisting of droplets as small as 1 micron, this type of spray increases the rh without wetting and eliminates the need for drip trays, re-circulation systems and maintenance intensive high pressure systems.

Non-drip and Self-cleaning Valves

As well as the quality of the spray performance, the nozzles come complete with a non-drip and self-cleaning valve, meaning they are virtually maintenance free. The unique valve design means that control is easy and as the valve self cleans the nozzle every time it is switched on/off there is no risk of the nozzle blocking

Our Ultrasonic Dry Fog system is not confined to new bread coolers only, a retrofitted upgrade to the existing traditional air washer humidity control system is available.

Between Sealpump and selected partners, we can design, manufacture, supply and install a brand new, much more efficient humidification system in your bread cooler. This new Dry Fog system will immediately increase efficiency, dramatically reduce your running costs and improve your product.

Our Dry Fog cooler upgrade system includes removing the existing air washer water spray system, which can include hundreds of nozzles, removal of sparge pipes, eliminator blades and high energy usage pumps.

We then replace all this high maintenance equipment with our Dry Fog Humidification system, which includes a small number of Dry Fog nozzle assemblies complete with nondrip & self-cleaning valves, water filtration and control unit which offers extremely accurate humidity control, where each nozzle can be controlled individually to ensure that the exact humidity is reached, maintained and controlled throughout the process.

The second also highlights the wetting and moisture fallout of the old style water nozzles, the Dry Fog nozzles do not wet due to droplet sizes being so small (1-5 micron), therefore, the bakery benefits from huge water savings and savings on water disposal.

Savings

No eliminator blades required

No sparge pipes required

No brittle sparge pipe nozzles to replace

Less power consumed – no pumps needed

No pump filters to replace & monitor

Less water consumed – no dump cycle

Hygiene hours halved

Less maintenance required

Full nozzle change in less than 2 hours

No nozzle leakage, dripping or blocking

Advice

Fog nozzles need to be spaced as far apart as possible

Ideally the fog generated should be given enough distance to travel so that the fog is fully absorbed into the airflow

Airflow to be constantly monitored by Temp & Humidity Probe

PLC controlled to be gradual rather than aggressive

One nozzle per solenoid – Cooler upgrades use a maximum of 26 nozzles

For Technical Information and Specifications,

download our PDF