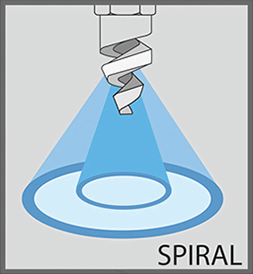

What are Spiral Nozzles?

Spiral nozzles produce either a spiral full cone or hollow cone spray pattern, the spiral full cone pattern is developed from a series of concentric hollow cones which combine to give a full cone effect.

The liquid is atomised into small droplets by a continuously descending spiral, therefore enters and exits with no internal restrictions through the nozzle. The result is a higher discharge velocity so low pumping pressures can be used to produce the required atomisation.

We offer a wide range of flow rates and pressures with spray angles available from 60° to 180°. All spiral nozzles benefit from an unobstructed flow passage thus minimising clogging potential.