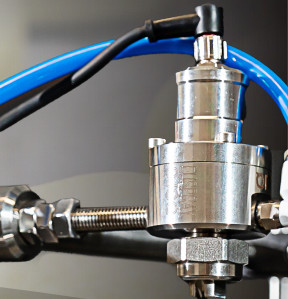

Demo Speedyjet Spray System

Speedyjet Spray System For Food And Bakery Applications

Demo Speedyjet Spray System

Description....

Many food and bakery manufacturers and processes have applications that benefit from well designed spray systems that can assist either with direct product quality or process improvement. Whether spraying ingredients, coatings, glazes, release agents or just water, being able to control the amount of material used, reduce waste and improve quality is essential in optimizing production and product quality.

Our electrically actuated Speedyjet spray systems are the ideal solution for all these applications as they can reduce waste, eliminate misting and overspray and reduce rejected products and downtime often experienced by manufacturers with inefficient spray systems.

We have experience in spraying almost all materials within the food and bakery industry and are able to help with the design and supply of the most efficient, reliable spray system.

Sealpump can also carry out initial spray tests at our facility in order to help select the best spray solution.

Applications

- Spraying food coatings & flavourings

- Spraying glazes onto baked goods

- Spraying alcohol (ethanol) onto food packaging to extend shelf life

- Applying egg wash to baked goods

- Spraying anti-microbial solutions onto meats and salads for food safety

- Moistening spray systems for seed and topping adhesion

- Tin & pan lubrication

- Spraying mould release agents

- Spraying mould inhibitors

- Applying low volumes of water to combat water loss

- Dough splitting/scoring

- Many more

Benefits

- High speed pulse of up to 4500 cycles per minute is suitable for high speed production lines and allows production to be increased

- When used with the Speedyjet Spray Controller it gives precise control over the flow rate and spray angle

- Flow rate can be easily adjusted simply by adjusting the on/off of the spray cycle on the control panel screen

- Different flows can be achieved with a single nozzle size

- Low flow rates are possible with larger orifice nozzles, reducing the risk of nozzle blockage

- Food grade nozzle & system available

- Eliminates misting and potential overspray improving product quality and improving process cleanliness

Bottom Content Goes Here

This is the bottom content This is the bottom content This is the bottom content This is the bottom content This is the bottom content This is the bottom content This is the bottom content This is the bottom content This is the bottom content This is the bottom content

This is the bottom content This is the bottom content This is the bottom content This is the bottom content This is the bottom content This is the bottom content This is the bottom content This is the bottom content This is the bottom content This is the bottom content This is the bottom content This is the bottom content This is the bottom content This is the bottom content This is the bottom content